Alpha Anodising can improve the appearance and performance of your finished product by pre-treating it before the actual anodising process takes place using a range of mechanical and chemical techniques which can also be combined to provide a combination of contrasting finishes.

Polishing

Polishing will impart a shiny/gloss finish to the part. A mirror polished finish often proving the most popular. Some grades of aluminium are more suitable than others in order to achieve mirror polished results, so if this is the finish you require please speak to Alpha for advice on the best material to use.

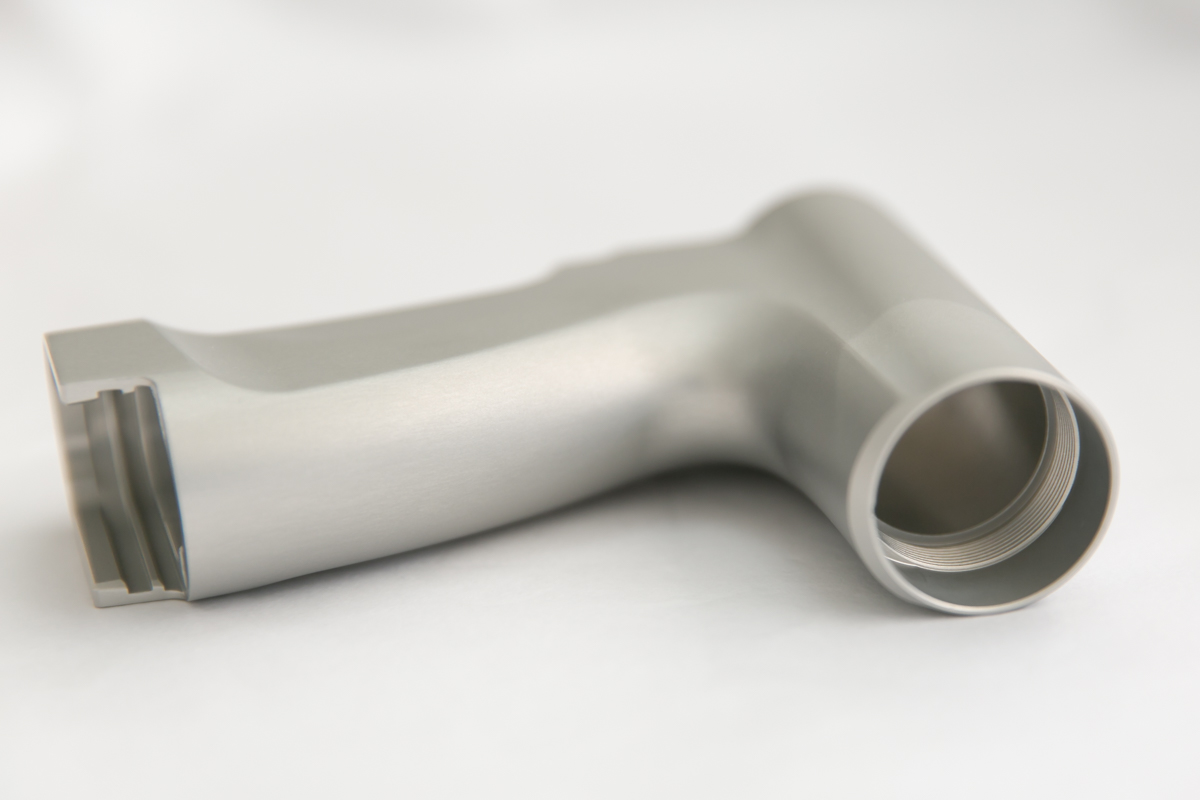

Beadblasting

Bead blasting can not only remove fine machining lines but produces a uniform textured ‘matt’ finish to the part. The resulting appearance can be varied to give a very fine satin texture or a coarse texture depending on the size and type of the bead media and pressure used. When used in conjunction with our ‘chemical brightening’ pre-treatment, we are able to achieve anything from a subtle lustre to a bright finish.

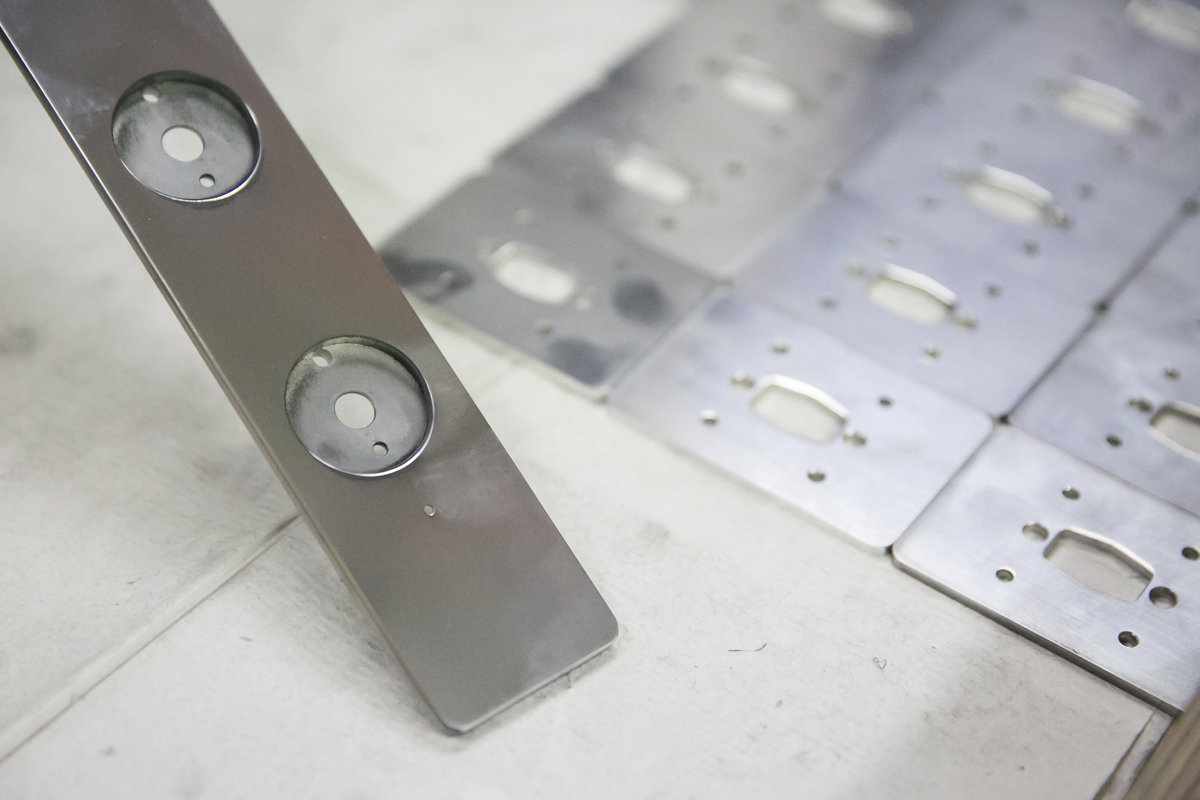

Brushing

Brushing produces a textured ‘grained’ finish. Again the resulting appearance can be varied to produce a lighter or coarser texture depending on the media grade of brushing belt used. Brushed finishes can be used in conjunction with bead blasting, etching and brightening in order to achieve a variety of resulting finishes. Please note that coarser brushed finishes do not always provide a suitable surface for printing onto.

Etching

Produces a matt even finish and can be used to remove very fine machining lines and minor surface scratches.

Brightening

Produces a brighter more lustrous finish and can be used in conjunction with the mechanical textures in order to vary the appearance of the component. Not all alloys brighten well, so please speak to Alpha prior to selecting your alloy if you require your component to be brightened.